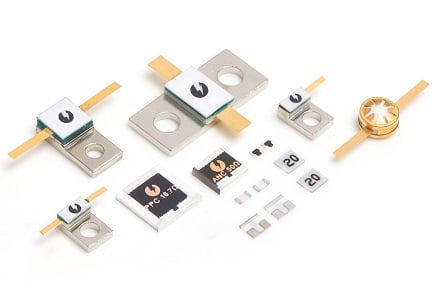

Powerfilm is APITech’s line of surface mount resistive products, including surface mount attenuators, terminations, resistors and equalizers. These highly configurable components are designed for high power, high frequency, and high reliability applications.

Powerfilm surface mount resistives are found in satellites, medical equipment, test and measurement devices, and supporting the newest military and commercial communications systems.

Powerfilm chip attenuators are used to help balance signal levels inside radar systems. High reliability and precision were critical here.

Similarly, an MRI manufacturer recently selected Powerfilm due to its high power handling in a non-magnetic construction.

Powerfilm surface mount attenuators are also commonly selected for DAS installations. Available for up to 250 watts and up to 18 GHz, they are designed to uniformly reduce power of the RF signal while generating only a small reflection under any operating conditions.

Powerfilm surface mount attenuators are also commonly selected for DAS installations. Available for up to 250 watts and up to 18 GHz, they are designed to uniformly reduce power of the RF signal while generating only a small reflection under any operating conditions.

Powerfilm’s small size and weight, and APITech’s ability to build surface mount attenuators to scale have also proven important criteria for DAS integrators.

Powerfilm has even become the go-to choice for cryogenic applications like quantum computing. In part because Powerfilm’s cryo chip attenuators work to near absolute zero.

In addition, several major high-frequency Test & Measurement calibration systems OEMs have selected Powerfilm rod resistors to support their metrology products, as we can provide custom sizes and custom Ohm values.

Along with frequency and power requirements, Test and Measurement applications require strict electrical and mechanical tolerances. The Powerfilm application engineering team helped validate the customer's application requirements and uncover additional opportunities to deliver optimized performance.

Powerfilm surface mount resistives can be customized by power, frequency, size, and finish. Our engineering team can assist you in customizing Powerfilm to match your exact RF performance, power handling and installation requirements. This also includes any material and environmental requirements, plus the ability to test to military and space level qualifications. We can also make Powerfilm available to you as a design kit.

Core differentiators of APITech’s Powerfilm include:

- Available in surface mount chip, flange, pill, and rod implementations

- Frequency applications from DC to 40 GHz

- Power applications from 100mW to 1000 Watts

- Small size-weight/low cost/compatible optimized for automated high-volume assembly (SWAP-C)

- Support for both high-performing BeO and environmentally-friendly AlN solutions

- Support for high-frequency solutions with thin film, and high-power solutions with thick-film resistors

- Multiple terminal/wrap configurations available

- MIL-DTL-3933 and other MIL-SPEC testing available

- Installation options include soldering, wire-bonding, hybrid, and coaxial assembly

- In-house component and circuit design

Powerfilm is designed, tested, manufactured and supported from our facility in the United States.

Learn More

Learn More

Learn more about APITech's Powerfilm offerings on our Resource Page:

.jpg)

News Blog

News Blog

Let Us Know What You Thought about this Post.

Put your Comment Below.